![]()

We recognise that every project is unique and are thrilled to be at the forefront of cutting-edge advancements in silicone 3D printing. Unlocking realms of creative possibilities in additive manufacturing. Our expertise enables us to offer tailored solutions, effectively addressing challenges from various industries worldwide. Join us as we continue to innovate and push the boundaries of silicone technology.

Polymer Systems

Technology Limited

3D Printing Silicone

Liquid Silicone Rubber for additive manufacturing

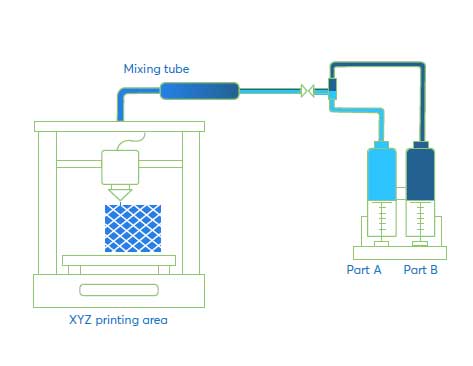

Liquid Silicone Rubbers (LSRs) for additive manufacturing from NuSil® offer unique rheological properties for use in extrusion based additive manufacturing for a variety of applications.

Historically, LSRs have been molded into parts, commonly through liquid injection molding.

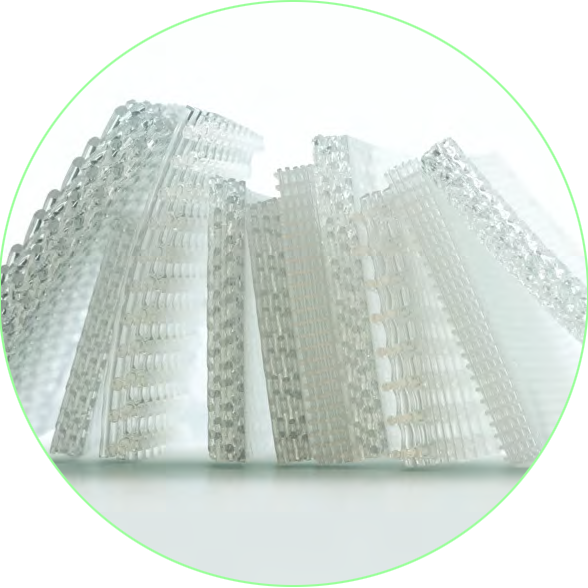

Printable LSRs allow for lab scale prototyping of complex geometries without compromising on the physical properties of the resulting material.

Low volume production of customized parts can also be achieved with our printable materials.

CURE CHEMISTRY

NuSil’s printable LSRs are addition cured, 2-part systems that are optimized for low temperature vulcanization. This platinum curing chemistry does not produce volatile leaving groups and results in minimal shrinkage of the printed part. Additionally, no steps are needed after curing to remove biproducts. NuSil offers dimethyl and diphenyl LSR options with various physical properties

Contact us for more information…